GlobalTCO

Total Cost of Ownership for Global Sourcing and Manufacturing (CTI No. 9864.1 PFES-ES)

Researchers:

Prof. Dr. P. Schönsleben, Dr. R. Alard, P. Bremen, C. Schneider, G. Finke

Partners:

Scientific:

ETH Zurich, BWI Center for Industrial Management

Asia Research Center – University of St. Gallen

Industrial:

ALSTOM (Switzerland) Ltd

SMS CONCAST AG

Hocoma AG

Komax AG

maxon motor ag

Dissemination:

external page Global-production.com

SVME Schweizerischer Verband für Materialwirtschaft und Einkauf

Financed by:

partially financed by CTI No. 9864.1 PFES-ES

Website:

Background:

Outsourcing of manufacturing capacities from Western Europe to countries commonly seen as low-cost countries, like Eastern European countries, China, India and the ASEAN countries, is a widespread phenomenon with increasing impact on Swiss companies. The main reasons for outsourcing are cost savings, the need for market development and technological requirements.

However, especially regarding cost savings, companies realize that they cannot turn over the frequently praised lower purchasing costs in the expected way. Especially when outsourcing manufacturing capabilities for components that are subsequently delivered to Western Europe for final assembly, companies struggle a great deal and often miss predefined targets. Unfortunately, this is often detected too late and leads to relocation projects and high financial implications in many cases.

Motivation:

Today, enterprises are aware of the fact that the total cost of ownership (TCO) for manufacturing and sourcing of components in low-cost countries is increasing. On the one hand, well identified costs like transport costs and personnel costs are rising, and on the other hand, companies are becoming more aware of the additional costs that are hidden in the overhead costs.

However, companies often find it difficult to identify and document this TCO in a binding and comprehensible manner. Even large companies with a lot of experience in manufacturing and sourcing in, for instance, Asia or Eastern Europe, are interested in a methodology for a systematic identification of these costs. The project “Total Cost of Ownership for Global Sourcing and Manufacturing” will develop this methodology.

Objectives:

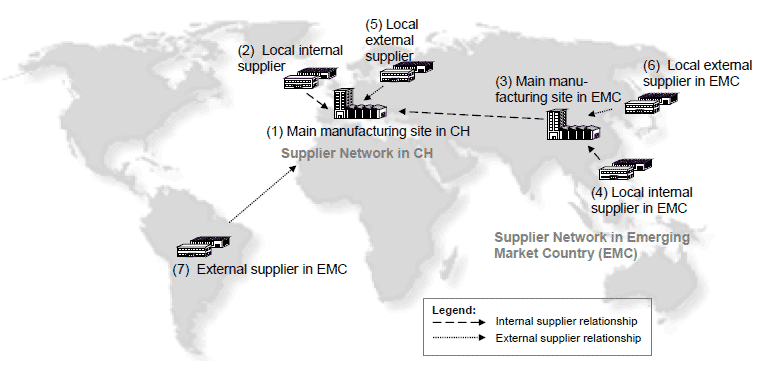

The aim of the project GlobalTCO is to support industrial companies with decision-making methods to outsource the right products and components to the right regions in the world and to collaborate with the right business partners in a sustainable manner.

Based on the approach of total cost of ownership, microeconomic and macroeconomic aspects of decision-making for global sourcing and manufacturing are considered. Examples of results are:

- Method toolbox supporting TCO analysis (microeconomic aspects)

- Method toolbox supporting regional assessment (macroeconomic aspects)

- Implementation methods and processes for regional assessment and for TCO calculation

Activities completed in 2010:

In 2010, the solution finding for supply chain design (work package 3) will be completed. This concludes the development of a TCO tool containing microeconomic as well as macroeconomic aspects, and the execution and evaluation of a survey. Further, the developed tools and insights will be applied and implemented into the process landscapes of the industry partners (work package 4). Implementation methods and processes will be developed and followed up by representative case studies. In addition, dissemination (work package 6) will be fostered by the development of seminars, publication of articles, and participation in conferences.

Activities completed in 2011:

The project was completed in the first half of 2011. In the last consortium meeting in June, the industrial partners exchanged experiences they had gained from the practical implementation and application of the developed tools. Transfer and dissemination of the knowledge created in the project continued to be pro-moted through seminars, publication of additional articles, and conference participations. Dissemination was further facilitated by implementing the developed tool in two additional companies. The project was concluded with a comprehensive final report containing all relevant information about the project. Industrial, academic, as well as institutional partners expressed their full satisfaction with the outcome of the project.